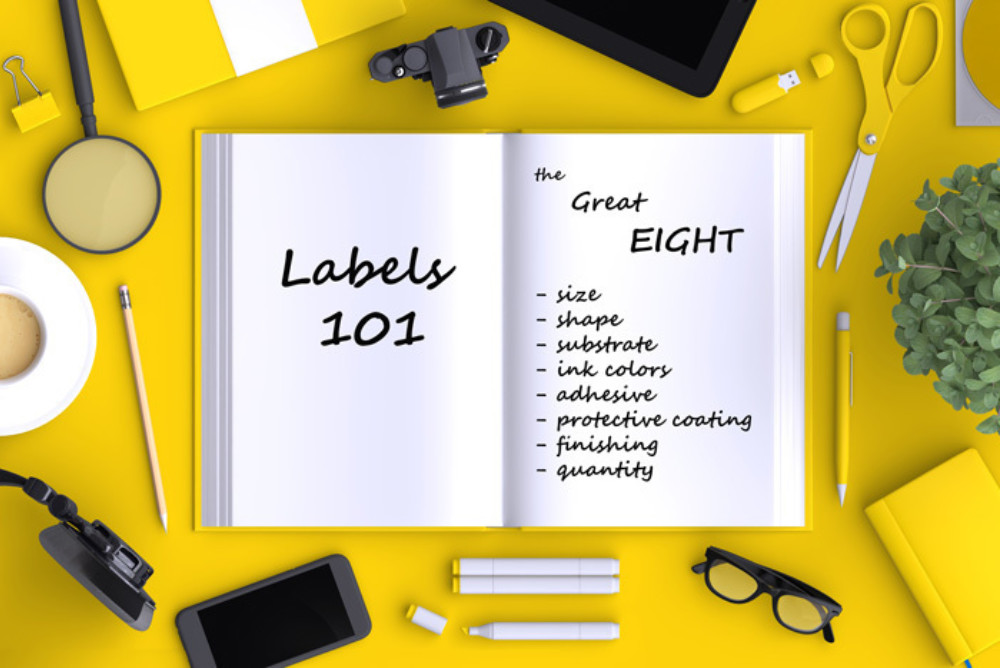

The GREAT EIGHT

Welcome to Labels 101! The first principles any student of this class will learn is what we like to call The Great Eight. The Great Eight is the distillation of the vast variables a custom label can have into eight core categories. These categories are: size, shape, substrate, ink colors, adhesive, protective coating, finishing and quantity. Let’s explore each of these specifications in greater detail.

Size

The size of a label equals its precise dimensions for width x height and given the accuracy of print technology today can be specified up to four decimal places. The label industry still uses the imperial system as the standard system of measurement, therefore the dimensions are most commonly stated in inches. Generally, the size of the label has a direct relationship with the unit cost of the label, since the larger the label, the more material is being used.

Shape

Shape is pretty self-explanatory; it refers to the form a label will be cut into, for example a circle, rectangle, oval or scallop. Nowadays digital printers equipped with any-contour or free from finishers enable virtually ANY shape for a label. In the case of cornered shapes, such as a square or rectangle, the corners must be specified as either rounded

corners or square corners. A shape that doesn’t fall into a common geometric classification is referred to as a “special custom shape.” Shape is invariably linked to size, so when a describing a label, start with both size and shape, such as a 1” x 5” square corner rectangle or a 2.13” x 3.46” special custom shape.

Substrate

What will this label be printed on? Substrate is the material that provides the surface for which the artwork will be inscribed. Since we’re talking about custom stickers, you can assume that one side of the substrate will be imbued with a pressure sensitive adhesive, or in other words, will have a sticky side. Paper, poly, vinyl, foil – these are all examples of substrates, however given the vast array of label substrate options, you will need to be more specific when characterizing a substrate. For example, a white gloss paper or a matte silver foil.

Ink Colors

As you can imagine, ink is a critical part of custom printing and as the industry becomes more and more digitized, new ink technologies advance bringing new capabilities and new challenges for this ancient substance. In the context of the Great Eight, ink colors can identify a method of printing, such as CMYK, or specific spot colors, such as black and PMS 186 red. Inks can be liquids, powders, pastes, resins, foils or a combination of these elements. Printed ink is very different from the digital representation of ink you see on a computer monitor and although this may seem obvious to some of you, it cannot be stressed enough how important it is to clarify the expectation of color output on a custom printed label.

Adhesive

Adhesive is intrinsically connected to substrate since all substrate options we offer for label printing are acquired from the manufacturer with the glue already converted into a printable material. Application will often dictate adhesive and depending on the importance of certain factors, such as durability or removability, the adhesive choice may supersede some of the other Great Eight specs. Adhesive options include static cling, removable, standard, hi bond, block out, extra permanent and “RTS” for rough textured surfaces. Another facet of adhesive to be aware of is its situation on the label, which can either be on the back side or the face side.

Protective Coating

Any film or layer that is applied overtop of the substrate and printed inks is considered a protective coating. It may take the form of a lamination, varnish, clear coat or scratch guard, and some of these options can be further particularized into matte or gloss, UV or sunscreen. Protective coatings are added to enhance label durability, prevent certain inks from washing off or scratching, protect against abrasion, fading or environmental impacts and alter the final finish or overall look and feel of the label.

Finishing

Not to be confused with the “finish” of a label, the term finishing refers to the way an order of custom printed labels will be supplied to the end user. Labels can be finished on rolls, in singles or on sheets. Rolls can have 1” or 3” or no cores, they can be perforated between labels or printed 2-up across on the roll, there are eight different rewind directions (meaning the orientation the copy comes off the roll), front and back labels can be printed alternating on the same roll and so on. Singles can be kiss-cut or what is commonly called die-cut with or without a score tab, they can be bundled, shrink-wrapped, bagged or just free floating in a box. Laser sheets are supplied ready to insert into home or office laser printers, so they are often sheeted at 8.5” x 11”. Wide format sheets are cut down from larger sheets to fit into packaging for shipment. A cardinal rule of finishing is: unless otherwise specified, the press operator can finish rolls or sheets however he or she sees fit.

Quantity

Lastly, the straightforward specification of how many labels need to be printed. There are various MOQ’s (minimum order quantities) that vary from product to product you should familiarize yourself with, such as the minimum order for custom seals is 500 seals but the MOQ for domed decals is 50 pieces. When multiple versions or copy changes are present, careful documentation of quantity per version is essential as the quantity breakdown can be split however the client requires. Quantity price breaks occur at regular intervals of 100, 250, 500, 1000, 2000, 3000, 5000, 10,000 and so on, and sometimes it is more cost effective to order 1000 labels than 850, given the change in unit cost at a price break.

Understanding these eight basic principles to printing custom labels will go a long way in the compartmentalization of the countless variants confronted in this industry. Every custom label project is unique in some way but applying the Great Eight will help you classify, clarify and comprehend what kind of label the client is looking for and how it will be achieved.