Label Finishing Options for Custom Printed Labels

There are so many variables in custom label printing!

How would you like your labels finished? An order of custom stickers can be finished on rolls, perforated rolls, in singles (with or without score tabs) or on sheets. We can also customize the finishing to suit a particular machine application requirement. What are the best label finishing options? Keep reading!

Sticker finishing - everything you should know

The specific sticker finish you are ordering can limit or determine how your order will be finished, for example custom embossed foil seals are finished exclusively on rolls and screen printed decals are supplied as singles often with a score tab.

Rolls

Most orders of custom labels are finished on rolls. These custom labels in rolls may contain cores, which are cardboard circles the labels on the liner are wrapped around, but typically they are just wrapped into a manageable size around themselves. The press operator typically determines roll quantity unless otherwise specified, which results in rolls of 1000 or 500 but not always, so if roll quantity is important be sure to bring it up when you request a quote.

Rewind and Machine Application

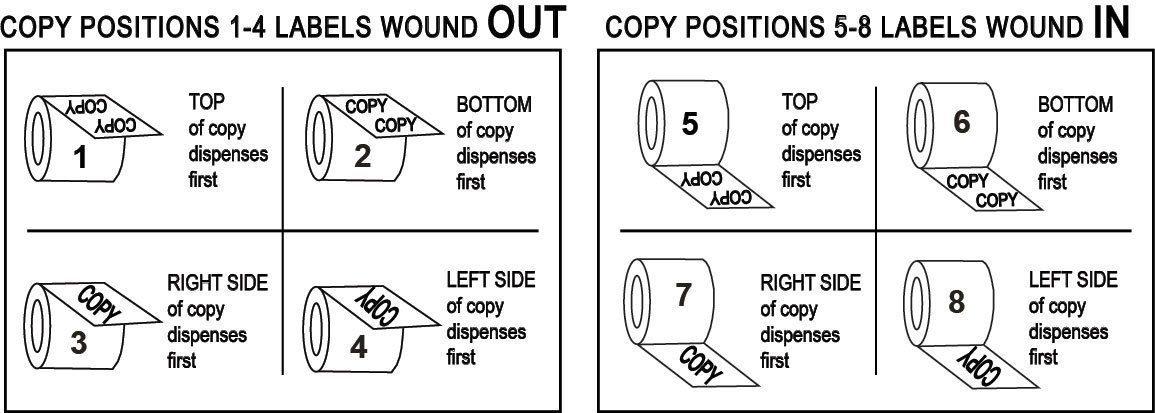

Rewind refers to the direction the labels will come off the roll, for example rewind #3 means the right side of the copy will come off the roll first. If a machine will be applying your labels, it is paramount that you provide your printer with the machine’s specifications to ensure your finished labels will be compatible with your machine. In the case of this sticker finishing, you will need to specify the core size, rewind direction, quantity per roll or the maximum outer diameter, maximum liner width and sometimes even the gap between labels.

Perforated Rolls

Perforated rolls mean that the liner will be perforated between each label on the roll, which makes it easy to tear the labels cleanly from the roll. This label finishing option is useful if you are planning to distribute individual labels or decals at events or in mailings, that sort of thing.

Singles

Finishing stickers as singles is pretty self-explanatory; however there are slight variations to be aware of. The terms “kiss-cut” and “die-cut” are commonly applied to this type of finishing, but these words have broader meaning in label printing and not all printers use them exclusively to describe singled stickers. Generally speaking, “kiss-cut” means that the cutting instrument cuts through the substrate to the precise point of the liner but doesn’t slice through the liner. “Die-cut” means the use of a die to cut the sticker, as opposed to a blade or laser. Labels cut with a die can also be kiss-cut, provided the die doesn’t cut through the backing paper. However, many people use “die-cut” to describe a singled sticker where the liner has been cut through leaving no evidence of backing paper around the edge of the sticker. In these cases, it is useful to have a score tab so the backing paper can be easily removed from the sticker.

Score Tab

The last but one sticker finishing is “score tab”, meaning a little slit through the liner on the back of the decal or along the side with a waste strip to ease the removal of the sticker from the liner. Most bumper stickers are singled and die-cut through the backing sheet, which can be problematic to remove hence the need for a handy score tab.

Sheets

Any decals produced on a wide format printing press will typically be produced with cut sheet finishing, which means that they are cut down from the large media that comes off the press in order to fit packaging for shipment. The number of decals per sheet will depend on the size and shape of the printed decal, as well as the size of the sheet. Domed decals are normally supplied to the end user on sheets since the production of these stickers requires a flat surface to accommodate the pouring and curing of the polyurethane doming material. Wide format decals can also be cut down into singles, however there will be backing paper visible around the edges of the decal, and it does add cost. There is more material waste to create the space between decals for easy singling, and it takes additional time to cut them from sheets into singles.

The takeaway

Choosing label finishing options tailored to your products allows you to create durable, high quality stickers, and decals that can bring various benefits to your business. If you have any questions about your custom label project – contact us. We’re here to help!

Want to learn how to attract customers to your store with labels and stickers? Check out our blog!